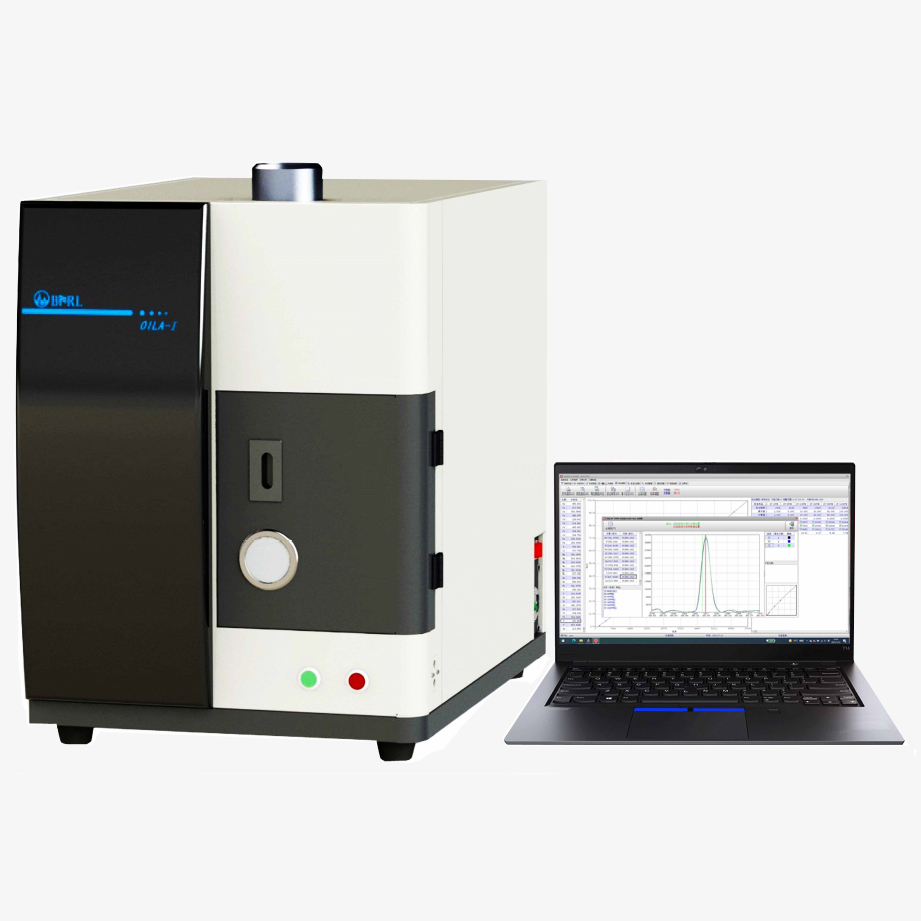

OILA-M OIL EMISSION SPECTROMETER

OILA-M Oil Emission Spectrometer is a proven means of precisely determining the elemental composition of wear metals, pollutants, and additives in lubricating oil, hydraulic oil, heavy fuels, coolant, and electrolyte. It is used as both a quality control tool and a machine health monitor.

Oil Emission Spectrometer, also known as the rotating disc Electrode Atomic emission spectrometer (RDE-AES), is a standard analytical instrument for oil element detection recognized in the global market. It is specially used to accurately quantify the composition of trace elements in various industrial oils and liquids.

OILA-M provides simultaneous multi-element analysis in tens of seconds without using gases and cooling water, and sample digestion pretreatment.

It is an effective tool for the preventive maintenance of equipment.

Applicaction

Industrial Oil Monitoring

Quality Control of Lubricants, Fuels, and Electrolytes

Cooling System Monitoring

Industrial Water Monitoring

Conforming Standard

ASTM D6595: Standard test method for determination of wear metals and contaminants in used lubricating oils or used hydraulic fluids by rotating disc electrode atomic emission spectrometry;

ASTM D6728: Standard test method for determination of contaminants in

gas turbine and diesel engine fuel by RDE-AES;

NB/SH/T 0865-2013: Determination of wear metals and contaminants in

used lubricating oils RDE-AES– Petrochemistry

SN/T 1652-2005: Method for determination of contaminants in Import and export gas turbine and diesel engine fuel RDE-AES–CIQ

HB 2009 4.1-2012: Determination of wear metals in aviation working fluid Part 1: RDE AES –Aerospace

DL/T 1550-2016: Determination of metallic copper and iron content in mineral insulating oils RDE-AES —— Power Industry

Specifications

| Application | |||

| Sample type | Lubricating oil, hydraulic oil, fuel oil, grease, antifreeze, cooling water, electrolyte, etc | ||

| Analytical Element | A1, Ba, B, Ca, Cr, Cu, Fe, Pb, Mg, Mn, Mo, Ni, K, Na, Si, Ag, Sn, Ti, V, P, Zn, etc (extensible) | ||

| Optical System | Working Parameter | ||

| Optical Structure | Pashen-Runge1 | Operating Temperature | 0℃~40℃ |

| Spectral Region | 201nm-810nm | Storage Temperature | -43℃~70℃ |

| Focal Length | 400mm | Operating Humidity | 0-95%RH, condensation free |

| Detector | Highly sensitive CMOS array | Injection Volume | ≤2ml |

| Temperature Control | Thermally stabilized; 37℃±0.1℃(adjustable) | Injection Mode | Rotating disc electrode |

| Power Source | Consumable | ||

| Voltage Input | 220V/50Hz | Top Electrode | Spectral pure graphite rod electrode |

| Power Consumption | ≤500W | Bottom Electrode | Spectral pure graphite disc electrode |

| Output type | AC arc | Sample Cup | High temperature oil cup |

| Mechanical Specifications | Standard Sample | ||

| Dimensions(mm³) | 835(W)×654(H)×734(D) | Standard Oil | 0#,10#,50#,100#,… |

| Weight | About 130kg | Standard Solution | 1000ppm,… |