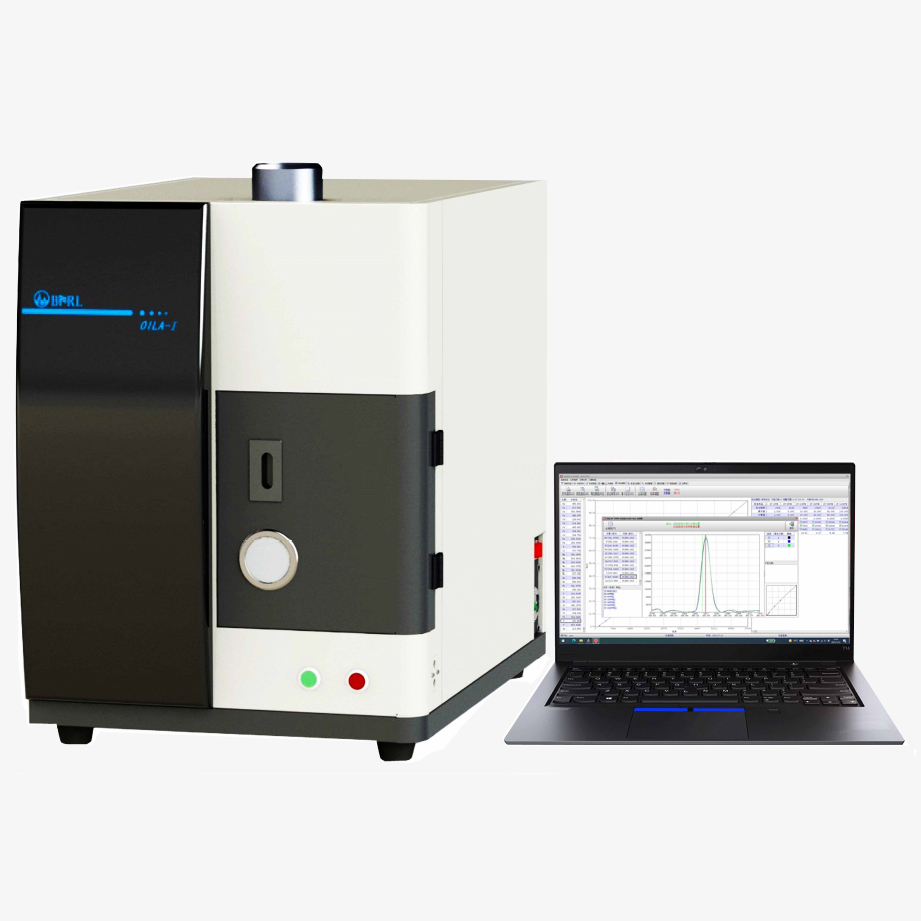

OIL-PHOTOWAVE

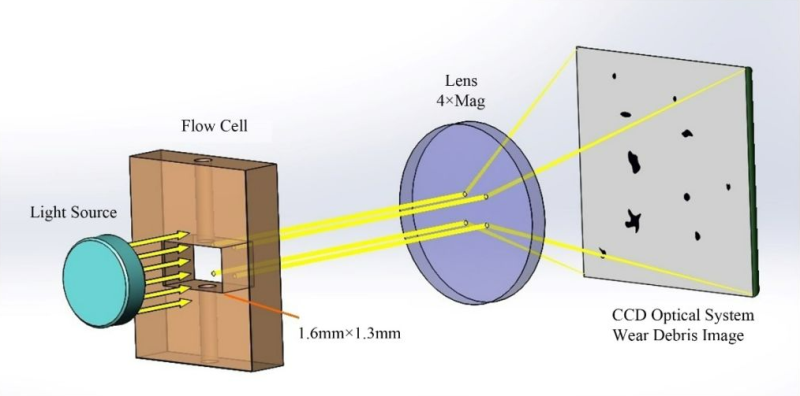

Principles

The OIL-PHOTOWAVE system uses an high speed imaging technology to intelligently capture the shape of particles flowing through the flow cell. Through the intelligent training algorithm, the morphological characteristics of the wear particles ( such as equivalent diameter, morphological factor and void ratio ) are obtained, and the particles are automatically classified and counted to determine the main wear form or contamination source and determine the contamination grade of the oil , easily assess machinery health in just minutes.

SPECIFICATIONS

| ITEM | PARAMETERS | |

| 1 |

Test Method |

High speed imaging |

| 2 |

Technique |

Intelligent image recognition |

| 3 |

Pixel Size |

1280×1024 |

| 4 |

Resolution |

2 um |

| 5 |

Optical Magnification |

×4 |

| 6 |

Particle shape minimum detection limit |

10 um |

| 7 |

Particle size minimum detection limit |

2 um |

| 8 |

Classification of wear particles |

Cutting, Sliding, Fatigue and Non-metallic |

| 9 | Contamination grade | GJB420B、ISO4406、NAS1638 |

| 10 | Functions | Wear particle and contamination grade analysis;Moisture, viscosity, temperature, dielectric constant analysis modules for options |

| 11 | Testing Time | 3-5 minutes |

| 12 | Sample Volume | 20 ML |

| 13 | Particles Range | 2-500 um |

| 14 | Sampling mode | 8 roller peristaltic pump |

| 15 | Built-in computer | 12.1 inch IPC |

| 16 | Dimensions (H×W×D) | 438mm×452mm×366mm |

| 17 | Power | AC 220±10% 50Hz 200W |

| 18 | Environmental Operating Requirements | 5°C~+40°C、<(95±3)%RH |

| 19 | Storage Temperature(°C) | -40°C ~ +65°C |

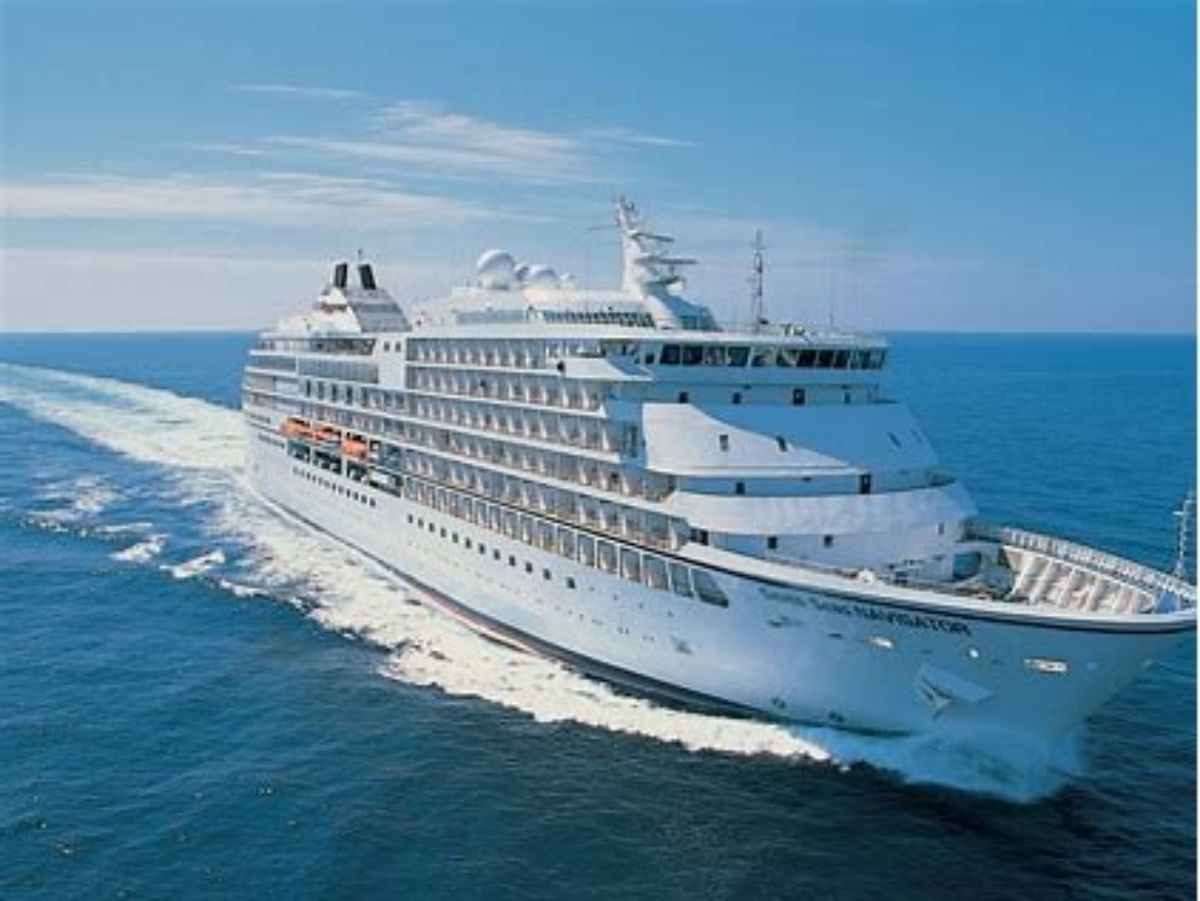

Typical Application

Ship, electric power, engineering machinery, industrial manufacturing, aviation, railway

Key Features

-Analyze the actual morphology characteristics and wear form of particle size above 10 um.

-Analyze the Contamination grade of particle size above 2um.

-Options of moisture, viscosity, temperature, dielectric constant multi-one analysis function mode.

-Wear particle morphology characteristics training database and daily analysis database.

-Wear classification and trend analysis.

-Using the training intelligent algorithm to classify and count the wear particles of cutting, sliding, fatigue and non-metallic ( water droplets, fibers, rubber, gravel and other non-metallic ) causes.