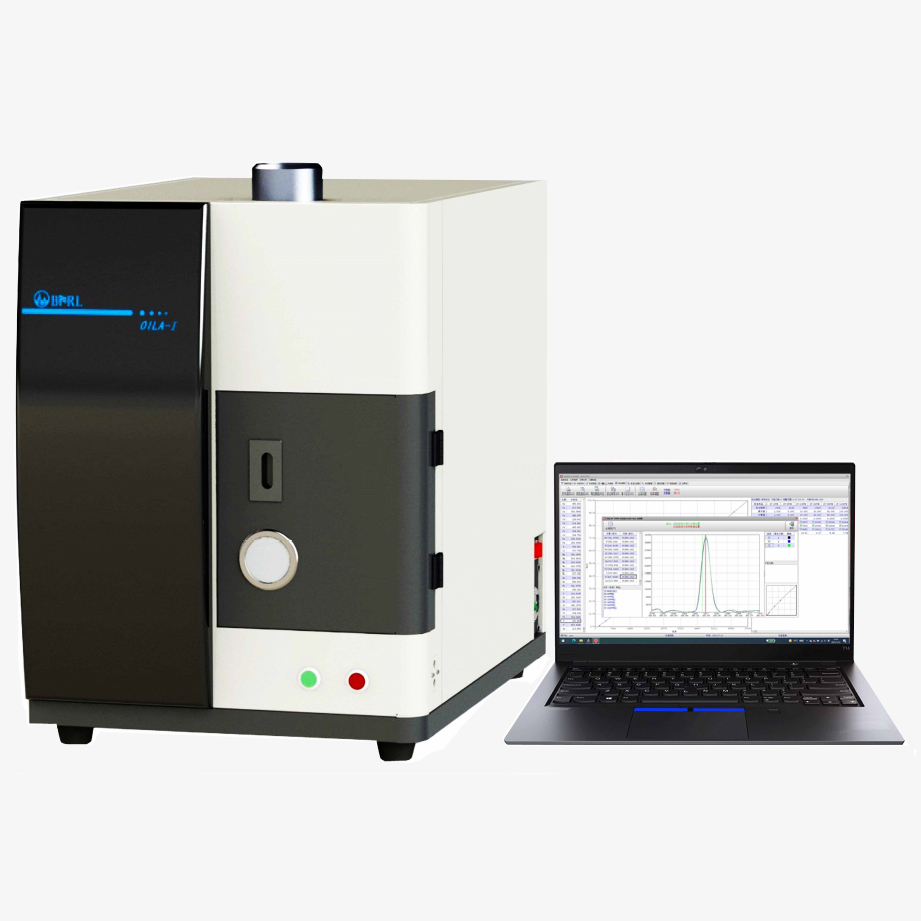

OILA-I OIL EMISSION SPECTROMETER

Product Video

overview

OILA-I Oil Emission Spectrometer is as a proven means of precisely determining elemental composition of wear metals, pollutants and additives in lubricating oil, hydraulic oil, heavy fuels, coolant and electrolyte. It is used as both a quality control tool and machine health monitor.

Oil Emission Spectrometer, also known as the rotating disc Electrode Atomic emission spectrometer (RDE-AES), is a standard analytical instrument for oil element detection recognized in the global market.

It is specially used to accurately quantify the composition of trace elements in various industrial oils and liquids.

OILA-I provides simultaneous multi-element analysis in tens of seconds without using gases and cooling water.

It is an effective tool for preventive maintenance of equipment.

Application

Monitor the wear condition of equipment and the pollution and aging condition of lubricating oil

·Industrial Oil Monitoring

Process preparation and monitoring of derivative or pollutant concentration in fuel oil

·Quality Control of Lubricants, Fuels and Electrolytes

Monitor the element concentration in the cooling system antifreeze

·Cooling System Monitoring

Measuring power plant cooling water and turbine wash water provides unique system condition insights and ensure compliant disposal or reuse

·Industrial Water Monitoring

characteristic

·Fast and Easy to Operate

- No sample preparation required without the sample dilution or preheating required by other technologies

-No gases and cooling water required

-Tens of seconds analysis time

-Minimal training/background required to operate -No highly skilled or trained users are required

·Stable and Reliable Structure

-Classical Pashen-Rungel optical path structure

- High precision multi-CMOS acquisition system

- Full spectrum measurement while ensuring good resolution and accuracy

-Overall structural light chamber and seismic system design to ensure stability

·Human Safety Protection Design

- Humanized excitation chamber design, more convenient sample replacement.

- Excitation chamber door safety interlock, electromagnetic shield design, to protect the safety of users.

characteristic

Intelligent Oil Analysis and Diagnosis Platform

- Integrating oil data trend tracking analysis and oil condition automatic diagnosis function;

- Multi-peak separation computing ability, a variety of digital filtering algorithm modules and adaptive background function;

- Real-time calibration, interference correction, element identification And measurement, trend analysis and diagnosis, historical tracing;

- Analysis software platform specially tailored for oil detection.

Electric Power

Gear box, bearing, Analysis of copper and iron content in

insulating oil

Petrochemical Industry

Equipment asset management,

Product quality control

Cooling water discharge detection

Electrolyte and electrolysis process

allocation

Mining/Engineering

Engine, hydraulic,

compressor systems,

Bearing monitoring,

fuel element monitoring

Ships

Engine set.

Generating set

Hydraulic system,

Cranes, etc.

Wear warning,

Seawater pollution

monitoring

Third Party Laboratory

Oil sample testing

Aviation

Turbine/turbofan engine,

Hydraulic landing gear system,

Wear monitoring and warning

Schools/Institutes

Teaching

Research

Locomotive Railway

Gear box,

The transmission

system,

Power systems, etc.,

Wear monitoring and warning,

Oil product testing

conforming standard

ASTM D6595 Standard test method for determination of wear metals and contaminants in used lubricating oils or used hydraulic fluids by rotating disc electrode atomic emission spectrometry

ASTM D6728 Standard test method for determination of contaminants in gas turbine and diesel engine fuel by RDE-AES

NB/SH/T 0865-2013 Determination of wear metals and contaminants in used lubricating oils RDE-AES —— Petrochemistry

SN/T 1652-2005 Method for determination of contaminants in Import and export gas turbine and diesel engine fuel RDE-AES -— CIQ

HB 2009 4.1-2012 Determination of wear metals in aviation working fluid Part 1:RDE-AES —— Aerospace

DL/T 1550-2016 Determination of metallic copper and iron content in mineral insulating oils RDE-AES —— Power Industry

Specification

| Application | |||

| Sample type | Lubricating oil, hydraulic oil, fuel oil, grease, antifreeze, cooling water, electrolyte, etc | ||

| Analytical Element | A1,Ba,B,Ca,Cr,Cu,Fe,Pb,Mg,Mn,Mo,Ni,K,Na,Si,Ag,Sn,Ti,V,Zn,etc (extensible) | ||

| Optical System | Working Parameter | ||

| Optical Structure | Pashen-Runge1 | Operating Temperature | -10℃~40℃ |

| Spectral Region | 201nm-810nm | Storage Temperature | -40℃~65℃ |

| Focal Length | 400mm | Operating Humidity | 0-95%RH, condensation free |

| Detector | Highly sensitive CMOS array | Injection Volume | ≤2ml |

| Temperature Control | Thermally stabilized; 37℃±0.1℃(adjustable) | Injection Mode | Rotating disc electrode |

| Power Source | Consumable | ||

| Voltage Input | 220V/50Hz | Top Electrode | Spectral pure graphite rod electrode |

| Power Consumption | ≤500W | Bottom Electrode | Spectral pure graphite disc electrode |

| Output type | AC arc | Sample Cup | High temperature oil cup |

| Mechanical

Specifications |

Standard Sample | ||

| Dimensions(mm³) | 500(W)×720(H)×730(D) | Standard Oil | 0#,10#,50#,100#,… |

| Weight | About 82kg | Standard Solution | 1000ppm,… |